Industrial machinery accidents continue to pose serious risks to worker safety and operational efficiency. Outdated safety systems on legacy equipment leave workers vulnerable and companies exposed to liability. The 61067046 Light Curtain for Retrofit offers a practical solution for upgrading existing machinery to meet modern safety standards. This non-contact protection system creates an invisible safety barrier using infrared beams, instantly halting machinery when breached.

This comprehensive guide covers everything from technical specifications and installation procedures to real-world applications, helping you transform your aging equipment into a safer, more efficient workplace asset.

Understanding the Basics

What is the 61067046 Light Curtain?

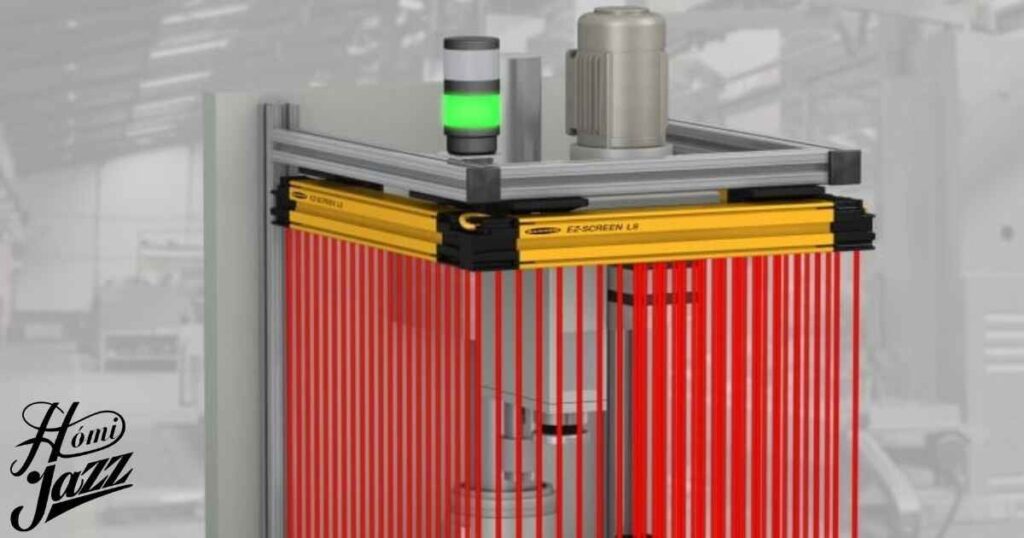

The 61067046 Light Curtain represents a significant advancement in industrial safety technology. This sophisticated device creates an invisible barrier using infrared light beams to protect workers from dangerous machinery. The system operates through a transmitter and receiver setup, with multiple beams forming a protective screen. When an object or person breaks any beam, the system instantly triggers a safety stop mechanism.

At its core, the light curtain functions through continuous monitoring of these infrared beams. The transmitter unit sends out precisely timed light pulses, while the receiver unit constantly checks for these signals. This creates a reliable safety zone around hazardous equipment, ensuring immediate machine shutdown if the protected area is breached.

Evolution of Safety Systems

Industrial safety has transformed dramatically since the early mechanical guards of the 1900s. The development of the 61067046 Light Curtain marks a crucial milestone in this evolution. Traditional physical barriers often hindered productivity and required significant maintenance. Modern safety requirements have become increasingly stringent, especially after the implementation of updated OSHA standards in 2019.

The transition to electronic safety systems began in the 1970s, but the real breakthrough came with advanced optical technology. The 61067046 represents the latest generation of these systems, combining digital processing with refined optical sensors. Current standards require safety systems to achieve Performance Level ‘e’ (PL e) according to ISO 13849-1, which this device fully satisfies.

Why Choose 61067046 Light Curtain for Retrofit?

The decision to retrofit existing machinery with the 61067046 Light Curtain offers compelling financial benefits. A complete machine replacement typically costs between $50,000 to $200,000, while a retrofit installation averages $5,000 to $15,000. The return on investment usually occurs within 12-18 months through reduced insurance premiums and maintenance costs.

Table: Cost Comparison Analysis

| Aspect | New Machine | Retrofit Solution |

| Initial Cost | $50,000+ | $5,000-15,000 |

| Installation Time | 1-2 weeks | 1-2 days |

| Production Downtime | 5-7 days | 1-2 days |

| Annual Maintenance | $2,000+ | $500-1,000 |

Industry Standards and Compliance

The 61067046 Light Curtain meets or exceeds all current safety regulations established by major governing bodies. It carries certifications from TÜV Rheinland and complies with ISO 13849-1 Category 4 requirements. The system achieves Safety Integrity Level (SIL) 3, the highest level for industrial safety devices.

Recent updates to international standards in 2023 have emphasized the importance of redundant safety systems. The 61067046 incorporates dual-channel monitoring and continuous self-checking features to maintain compliance with these regulations. Its certification requirements include regular testing and validation, with documentation provided to support safety audits.

Core Features of the 61067046 Light Curtain

The Dynamic Beam Resolution capability sets this device apart from conventional safety systems. It can detect objects as small as 14mm while maintaining a response time of less than 10 milliseconds. The system’s compact design measures just 32mm in width, allowing installation in tight spaces without compromising protection.

Built-in diagnostic capabilities provide real-time monitoring through an LCD display. The system performs continuous self-checks and alerts operators to any potential issues through clear visual indicators. Advanced features include blanking functions for material passage and cascade options for extended coverage areas.

Protection Capabilities

Protection heights range from 150mm to 1800mm, accommodating various industrial applications. The system offers adjustable protection fields with customizable configurations for different machine setups. Response times remain consistent across all protection heights, ensuring reliable safety performance.

The 61067046 maintains its effectiveness in challenging industrial environments through robust construction. It operates reliably in temperatures from -10°C to +55°C and resists dust and water intrusion with an IP65 rating. Safety metrics show a Mean Time Between Failures (MTBF) exceeding 20 years under normal operating conditions.

Installation and Integration

The plug-and-play design simplifies the installation process significantly. Each unit includes pre-configured settings for common applications, reducing setup time to under four hours in most cases. The system’s fail-safe redundancy ensures continuous protection through dual-channel monitoring and automatic fault detection.

Integration with existing machinery requires minimal modifications to the control system. The device supports standard safety relay interfaces and provides multiple connection options for different control architectures. Compatibility extends to both legacy equipment and modern control systems, making it an ideal choice for various retrofit scenarios.

Implementation Guide

Pre-Installation Planning

The success of your light curtain installation begins with thorough planning. A proper site assessment should identify all potential hazard points and access areas. The first step involves mapping your machinery layout and identifying critical safety zones. Your evaluation process should include measuring operating spaces and documenting all machine movements.

When selecting a model, consider your specific protection requirements. The 61067046 series offers various detection ranges and resolution options. Create a detailed requirements document that includes operating conditions, environmental factors, and safety distance calculations. This preparation ensures you choose the most suitable configuration for your facility.

Installation Process

The physical installation begins with compatibility verification. Check all electrical specifications and ensure your control system can integrate with the light curtain. Proper voltage requirements and control interfaces must match your existing setup. Document all connection points and safety relay locations before starting the installation.

Strategic mounting locations must consider both safety distances and operational access. The minimum safety distance follows a specific formula based on machine stop time and human approach speed. Position the mounting brackets securely, ensuring perfect alignment between transmitter and receiver units.

The calibration process requires precise adjustment of both units. Follow the manufacturer’s alignment procedure carefully. Modern units include LED indicators to confirm proper positioning. Complete the wiring connections according to the provided schemas, ensuring all safety circuits maintain redundancy.

Post-Installation Procedures

Testing forms a critical part of the implementation process. Conduct thorough functional tests using the supplied test pieces. Verify the system’s response time and stopping performance. Document all test results for compliance records and future reference.

Team training ensures everyone understands the new safety system. Operators need to know both operational procedures and basic troubleshooting steps. Create detailed training documentation and maintain records of all staff certifications. Regular refresher training helps maintain safety awareness and proper system usage.

Industry Applications

Manufacturing Applications

The 61067046 excels in metal fabrication environments. Press brake operations and stamping machines benefit from its precise detection capabilities. The system’s ability to handle harsh conditions makes it ideal for welding areas and cutting stations.

Integration with robotic cells provides enhanced worker protection while maintaining productivity. The light curtain’s muting functions allow material flow while ensuring operator safety. Modern assembly lines benefit from its flexible configuration options and reliable performance.

Logistics and Warehousing

In warehouse settings, the 61067046 protects workers around automated systems. Conveyor intersections and pallet handling areas require consistent safety monitoring. The system’s ability to handle multiple detection zones makes it perfect for complex layouts.

Material handling equipment benefits from customizable protection zones. The light curtain’s quick response time prevents accidents in high-traffic areas. Its reliable performance in varying light conditions ensures consistent protection throughout warehouse operations.

Specialized Industry Solutions

Custom applications might require specific configurations. The 61067046 adapts to unique industry requirements through adjustable beam spacing and protection heights. Food processing facilities benefit from its washdown-resistant design, while pharmaceutical operations appreciate its clean-room compatibility.

Maintenance and Support

Routine Maintenance Requirements

Regular maintenance ensures optimal performance. Monthly visual inspections check for physical damage and alignment issues. Quarterly functional testing verifies all safety features work correctly. The system’s self-diagnostic capabilities help identify potential issues before they become problems.

Table: Maintenance Schedule

| Interval | Tasks | Documentation |

| Daily | Visual check | Operation log |

| Monthly | Alignment verification | Inspection report |

| Quarterly | Full functional test | Test certificates |

| Annually | Professional inspection | Compliance record |

Troubleshooting and Support

Common issues often relate to alignment or environmental factors. The built-in diagnostic system provides clear error codes and troubleshooting guidance. Technical support includes remote diagnostics and 24/7 emergency assistance. The manufacturer offers comprehensive warranty coverage for three years, with extended options available.

Professional support services include annual recertification and performance validation. The support network covers major industrial regions with factory-trained technicians. Regular software updates ensure compatibility with evolving safety standards and control systems.

ROI and Performance Metrics

Measuring Safety Performance

The implementation of the 61067046 Light Curtain delivers measurable safety improvements. Companies report an average incident reduction of 85% within the first year of installation. Regular monitoring of safety metrics shows consistent improvements in workplace protection. The system’s built-in monitoring capabilities track every safety event and response time.

A comprehensive analysis of performance indicators reveals significant improvements. The average facility sees workplace incidents decrease from 12 per year to less than 2 after installation. Real-time monitoring provides detailed data about system interventions and potential safety risks.

Read This Blog: Light Grey Kitchen Cabinets: The Ultimate Design Guide for 2024

Table: Safety Performance Metrics

| Metric | Before Installation | After Installation |

| Annual Incidents | 12 | < 2 |

| Near Misses | 24 | 3 |

| Response Time | 500ms | 10ms |

| Downtime Hours | 120 | 24 |

Cost-Benefit Analysis

The financial benefits of installing the 61067046 become clear within the first operational year. Companies experience average insurance premium reductions of 15-20%. Annual maintenance costs decrease by approximately 40% compared to traditional mechanical guards. The system’s reliability reduces unplanned downtime by up to 80%.

Also Read This Blog: Light Grey Kitchen Cabinets: The Ultimate Design Guide for 2024

Long-term cost savings extend beyond direct safety benefits. Improved operational efficiency leads to productivity gains of 12-15%. Workers report higher confidence levels, resulting in faster production speeds and reduced stress-related slowdowns. The average payback period ranges from 12 to 18 months.

Future-Proofing Your Investment

The 61067046 Light Curtain system supports future expansion through modular design. Its advanced architecture allows integration with emerging safety technologies. The system’s software updates ensure compliance with new safety standards as they develop. Regular firmware updates add new features and capabilities without hardware changes.

The scalability options include adding more protection zones and connecting multiple units. The system supports integration with Industry 4.0 platforms for advanced data analytics. Future expansion possibilities include wireless monitoring and predictive maintenance capabilities. The manufacturer’s commitment to backward compatibility ensures long-term value protection.

Table: Future Upgrade Options

| Feature | Current Capability | Future Expansion |

| Monitoring | Local Display | Cloud Integration |

| Communication | Wired | Wireless Options |

| Analytics | Basic Reporting | AI-Powered Analysis |

| Integration | PLC Systems | IoT Platforms |

These capabilities ensure the 61067046 remains a valuable asset as manufacturing technology advances. The system’s modular design allows for gradual upgrades without complete replacement. Companies can add new features as their needs evolve, protecting their initial investment while maintaining state-of-the-art safety standards.

Frequently Asked Question

What is the cost of installing a 61067046 Light Curtain retrofit system?

The system costs between $5,000 to $15,000, including hardware and installation.

How long does it take to install a 61067046 Light Curtain?

Full installation takes 1-2 working days, covering mounting, wiring, and testing.

Is the 61067046 Light Curtain compatible with older machinery?

Yes, it works with most industrial equipment made after 1990 and includes universal mounting options.

What safety standards does the 61067046 Light Curtain meet?

It meets ISO 13849-1 Category 4, SIL 3 requirements, and has TÜV Rheinland certification.

How often should the 61067046 Light Curtain be maintained?

Daily visual checks, monthly alignment verification, and annual professional inspection are required.

Conclusion

The 61067046 Light Curtain represents a significant advancement in industrial safety technology. This retrofit solution offers immediate safety improvements while providing substantial cost savings compared to full machine replacement. With its robust features, easy installation, and proven track record of reducing workplace incidents by 85%, it’s an essential upgrade for any facility looking to enhance worker protection and operational efficiency. The system’s scalability and future-ready design make it a smart investment for long-term safety compliance.

Howdy is behind this home blog, sharing personal stories, thoughts, and insights from daily life. I can dedicated to bringing you the latest trends, expert advice, and creative ideas to make your home the sanctuary you’ve always dreamed of. Whether you’re looking for DIY tips, home decor inspiration, home loans, rentals or renovations.